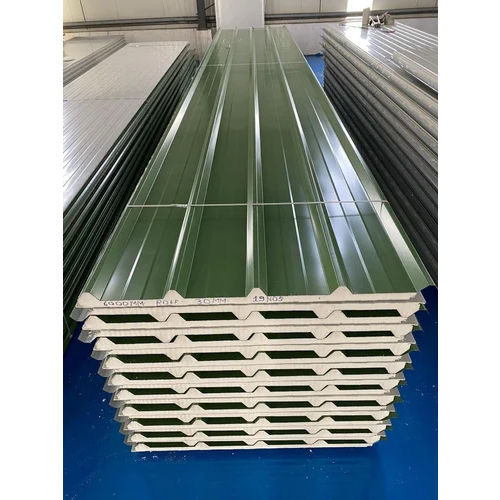

About Sandwich Puf Sheets

Sandwich Puf Sheets are three-layered panels consisting of an outer metal sheet, a polyurethane foam core, and an inner metal sheet. These sheets provide excellent thermal insulation with low thermal conductivity and heat conductivity. Coming in standard customizable sizes, with a green color and a pre-coated anti-corrosion layer, they offer durability and reliability. Suitable for roofing and wall cladding applications, these sheets have a high tensile strength and are lightweight for easy handling. With a maximum temperature resistance of approximately 80C, they are ideal for various industrial and commercial settings.

FAQs of Sandwich Puf Sheets:

Q: What materials are Sandwich Puf Sheets made of?

A: Sandwich Puf Sheets are made of metal and PUF (Polyurethane Foam) layers.

Q: How are Sandwich Puf Sheets installed?

A: These sheets are installed using screws and sealing tape, ensuring proper alignment during installation.

Q: What is the maximum temperature these sheets can withstand?

A: Sandwich Puf Sheets can withstand temperatures of approximately 80C, depending on the foam material used.

Q: What applications are Sandwich Puf Sheets suitable for?

A: These sheets are suitable for roofing and wall cladding applications.

Q: Are the dimensions of Sandwich Puf Sheets customizable?

A: Yes, the standard sizes can be customized according to specific requirements.