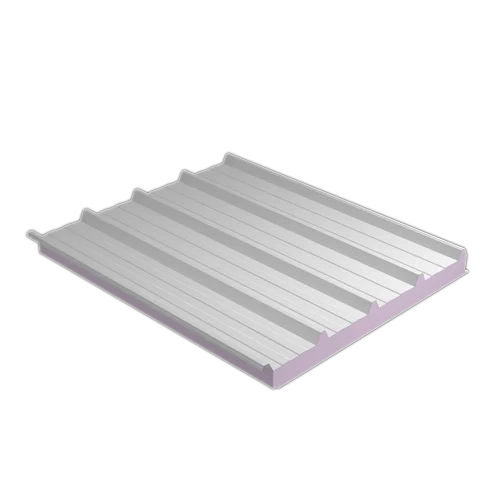

About Sandwich Insulated Puf Panel

The Sandwich Insulated PUF Panel features a three-layer structure of metal sheets with a Polyurethane foam (PUF) core, providing high thermal insulation and lightweight properties. With a coating of Pre-painted Galvanized Steel (PPGI) or Pre-painted Galvalume Steel (PPGL) and customizable color options, these panels offer excellent corrosion resistance. The panels have low heat conductivity, a density of 40 g/cm3, and a tensile strength of 250 MPa. Suitable for roofing and wall cladding applications, the panels come in customizable sizes ranging from 30mm to 150mm in thickness, with a standard width of 1 meter. The panels are surface-treated with pre-painting and galvanization, ensuring durability and longevity. With a thermal conductivity of 0.023 W/mK and the ability to withstand temperatures up to 80C, these panels provide efficient insulation and structural support for various industrial needs.

FAQs of Sandwich Insulated Puf Panel:

Q: What are the key features of the Sandwich Insulated PUF Panel?

A: The Sandwich Insulated PUF Panel offers high thermal insulation, lightweight construction, corrosion resistance, low heat conductivity, and a three-layer structure for enhanced durability.

Q: What materials are used in the construction of these panels?

A: The panels consist of a Polyurethane foam (PUF) core sandwiched between two metal sheets, coated with Pre-painted Galvanized Steel (PPGI) or Pre-painted Galvalume Steel (PPGL).

Q: How are these panels installed?

A: The panels can be easily installed using fasteners and sealants, making the installation process efficient and convenient.

Q: What applications are these panels suitable for?

A: These panels are ideal for roofing and wall cladding applications, providing both insulation and structural support.

Q: What is the maximum temperature these panels can withstand?

A: The Sandwich Insulated PUF Panel can withstand temperatures up to 80C, making it suitable for various industrial settings.